From Quarry to Kitchen: The Journey of Your Stone Countertop

Ever wondered how that beautiful slab of stone becomes the centerpiece of your kitchen? Join us on a fascinating journey from the depths of the quarry to the heart of your home as we explore the intricate process of creating a stone countertop. Learn about the different types of stone, how they are extracted from the earth, and the craftsmanship involved in turning them into exquisite countertops. We’ll take you behind the scenes of our fabrication process, showcasing the expertise and care that goes into every countertop we create. Whether you’re a homeowner planning a kitchen remodel or simply curious about the journey of stone, this blog will give you a newfound appreciation for the artistry and beauty of stone countertops.

The Journey of Your Stone Countertop

Welcome to an adventure we would like to take you on—a journey that starts deep in the Earth and ends up as the masterpiece in your kitchen—your stone countertop. Here, we introduce you to the process of transforming a piece of raw stone into an exquisite countertop—a testament to the craftsmanship and quality offered by Planet Stone.

Understanding the Types of Stone

The process begins with understanding the types of stone commonly used for countertops. The three most popular choices are granite, marble, and quartz, each showcasing exemplary stone countertop craftsmanship. These stones offer unique features and benefits.

Granite, an igneous rock, boasts variations in color and pattern that offer a uniquely natural aesthetic. Its hard nature makes it scratch, heat, and stain-resistant, ranking it high on functionality and durability. Marble, a metamorphic rock known for its luxurious appeal, adds a touch of elegance with its veined look. While it may require regular sealing, its timeless beauty is incomparable. Quartz, an engineered stone, offers a perfect balance of style and strength. The availability of quartz in various colors and its non-porous nature makes it an ideal fit for contemporary kitchens.

While each stone is unique, they share a common origin – being extracted from deep beneath the Earth's surface.

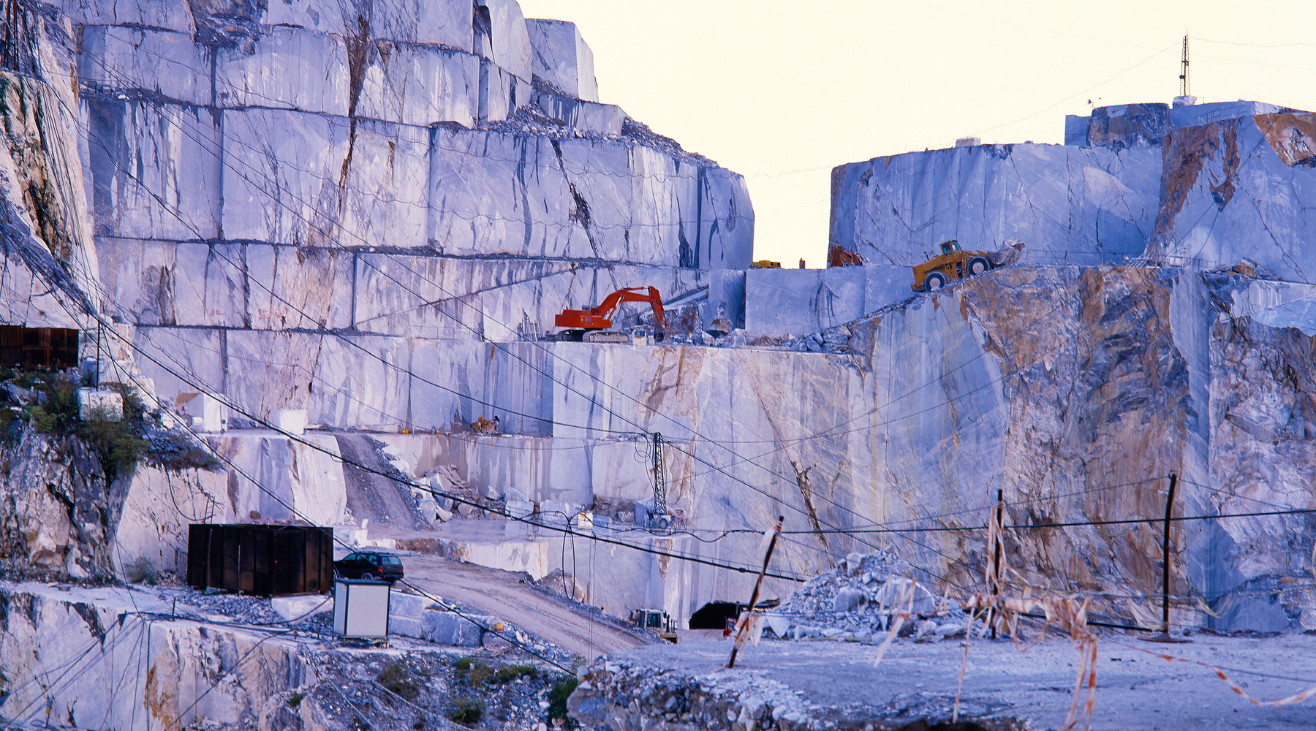

The Extraction Process

The process of stone extraction involves systematic planning and high-level precision. We start by carefully selecting a suitable location in a quarry. Then, large blocks of stone are extracted using advanced machinery, all while ensuring that safety measures are adhered to.

In addition to safety, we also focus on sustainable quarrying, understanding our responsibility toward the environment. Proper attention is given to water and dust management, waste disposal, and site rehabilitation.

In the next section, we will delve deeper into the exciting journey of transforming these blocks into dazzling slabs. Though the extraction phase might seem rugged and raw, it is the first critical step towards crafting stone countertops that encapsulate beauty and functionality in perfect harmony.

Countdown to Craftsmanship: The Fabrication Process

After the raw stones are extracted, the countdown to craftsmanship begins. The stone is first cut into slabs of uniform thickness using high-speed diamond saws. Cutting is followed by the shaping process, where the countertop edges are meticulously crafted per the design specifications. Each stone type has unique properties and requires distinct shaping techniques.

The final stage of stone countertop fabrication is the polishing and finishing process. Depending on the desired shine, the stone undergoes several rounds of polishing using progressively finer abrasives. Finally, thorough quality control checks ensure the slab fulfills all aesthetic and functional requirements.

The role of technology in stone countertop fabrication is of immense interest. While advanced machinery like CNC routers and stone polishers ensure precision and uniformity, the human role must be maintained.

The Installation: Completing Your Kitchen's Masterpiece

The stone countertop installation process is equally vital in the journey, showcasing the culmination of meticulous stone countertop craftsmanship. After the countertop is designed and crafted, accurate measurements and templating are performed at your kitchen site to ensure a perfect fit.

Once the countertop is delivered, professional stone countertop installation involves accurately fitting and securing the countertop, followed by sealing to protect the stone's surface quality. Sealing is crucial for porous stones like marble and granite, which may get stained. We always recommend professional installation to ensure longevity and durability. The stone countertop installation process culminates only with a thorough inspection and your complete satisfaction.

Crafting Masterpieces with Planet Stone

The journey of a raw stone from the quarry to become your kitchen's centerpiece is a testament to immense craftsmanship, skills, and technology. At Planet Stone, each process is carried out with absolute attention to detail, from extraction to installation. With stone countertop fabrication, each piece's journey from raw material to your kitchen is a testament to meticulous skill and dedication.

We hope this journey has fascinated and inspired you. Planet Stone's dedication to stone countertop craftsmanship ensures that each piece is not just a countertop but a work of art. We invite you to explore our website. Let us guide you through selecting and installing your stone masterpiece and creating a kitchen that truly reflects your style and sophistication. Let's create your kitchen's masterpiece together!